-

Publish Your Research/Review Articles in our High Quality Journal for just USD $99*+Taxes( *T&C Apply)

Offer Ends On

Ezegbe Chekwube Andrew*, Uzondu WisdomofGod Samuel, Ezegbe Amarachi Grace, Anikwe Chidera Celestine, Okafor Nnedimma Pauline, Odo Kenechi Benjamin, Onyia Oluebube Chisom, Agu-kalu Amarachi, Ugorji Anita Chidera and Uchenna Ch

Corresponding Author: Ezegbe Chekwube Andrew, Department of Pharmaceutical Technology and Industrial Pharmacy, University of Nigeria, Nsukka, Nigeria.

Received: February 20, 2025 ; Revised: March 10, 2025 ; Accepted: March 13, 2025 ; Available Online: March 21, 2025

Citation: Andrew EC, Samuel UW, Grace EA, Celestine AC, Pauline ON, et al. (2025) The Role of Polysaccharide Aerogel in Tissue Regeneration and Repair. J Pharm Sci Drug Discov, 4(1): 1-6.

Copyrights: ©2025 Andrew EC, Samuel UW, Grace EA, Celestine AC, Pauline ON, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Views & Citations

Likes & Shares

Aerogel-based biomaterials is an important subject in materials sciences due to their vast attention in different sectors. These materials possess unique properties that distinguish them such as low density. In the area of tissue engineering, there application has been documented in areas such as blood vessel, soft tissue, nerves, bone and cartilage. There are several steps involved in aerogel preparation. The first step involves the appropriate selection of a precursor material such as polymers, silica or carbon. Aerogels have a unique property which include the composition of mesoporous solid colloids that possess a light weight and a porous frame work structure. Aerogels also possess unique extraordinary physicochemical properties. Tissue engineering is a broad term that encompasses on using biocompatible materials to repair and replace damaged tissues. Notwithstanding, its diverse applications over the years, tissue engineering have had persistent hurdles which include the need to develop new novel biomaterials This article seeks to review the properties of aerogel and their preparation processes. The review also documented the challenges from current studies and future prospects were also discussed.

Keywords: Aerogel, Biomaterials, Biomedicine, Material science, Porosity

INTRODUCTION

The significant attention aerogels have gained over the years especially in the field of biomaterials cannot be over emphasized [1,2]. They have a unique property which include the composition of mesoporous solid colloids, which possess a lightweight and a porous frame work structure [3]. A definition given by Feng et al. defined an aerogel as a solid component that has a unique dispersion [4]. Aerogels are remarkable materials that possess extraordinary physicochemical properties [5]. Aerogel preparation involves several steps. They have diverse applications and ability to exist in different forms such as cylinders, spheres and monolithic shapes [6,7]. In the field of biomedicals, their application is widespread to other areas not limited to tissue engineering [8,9].

Tissue engineering is a broad term that encompasses on using biocompatible materials to repair and replace damaged tissues. Notwithstanding, its diverse applications over the years, tissue engineering have had persistent hurdles over the years which include the need to develop new novel biomaterials [10-14]. With these challenges in view, the promising avenue of aerogel-based biomaterials cannot be over-emphasized [15]. Some of the several reasons associated with the use of these materials include: its biocompatibility, biodegradability and mechanical strength [16]. Scientists have been able to incorporate the aerogel-based scaffolds in three-dimensional (3D) printing, thus enhancing its flexibility.

AEROGEL-BASED BIOMATERIALS AND THEIR UNIQUE PROPERTIES

Distinctive properties associated with aerogels include high porosity, low weight and surface area [17-20]. They help to increase their widespread applications in various fields. These exceptional qualities of the biomaterials to be easily handled and implemented in the human body is related to their low density and weight [21]. Some of the techniques used in the determination of aerogels include: scanning electron microscopy (SEM), small-angle scattering (SAXS), nuclear magnetic resonance (NMR) and X-ray diffraction (XRD) [22-26].

AEROGEL-BASED BIOMATERIALS AND THEIR PREPARATION TECHNIQUES

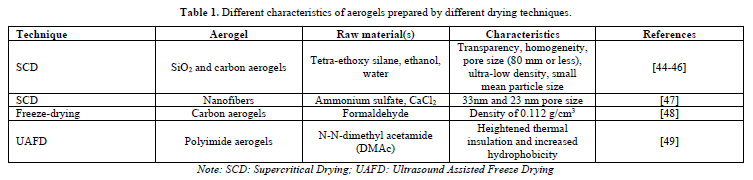

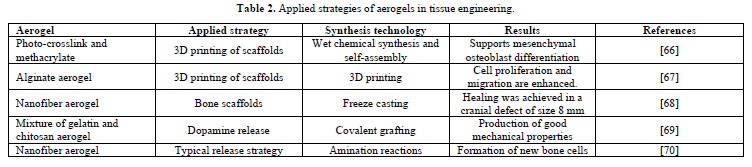

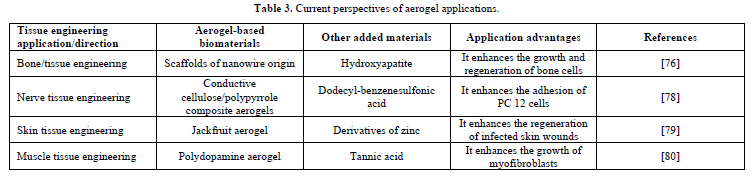

Several key steps are involved in aerogel preparation. The first step involves the appropriate selection of a material such as polymers, silica or carbon [27-28]. These precursor materials have their own unique properties. The sol-gel process is the first fundamental method employed in aerogel synthesis [29,30]. To enhance the strength of aerogels, there is to deploy various cross-linking strategies [31,32]. The production of nanofiber-derived aerogels (PNAs) by Qian [33], was based on the high porosity and surface area. The effect of aging on the aerogel’s microstructure has been documented. According to Kawakami [34], he deployed the use of water vapor in optimizing the aging process. The most prevalent methods among the afore-mentioned techniques are freeze-drying and SCCO2 drying [35-40]. Table 1 summarizes the drying methods on aerogel characteristics, while Tables 2 & 3 depicts the various strategies for aerogel preparation. Two unique characteristics mark out the supercritical drying technique. They include avoidance of structural collapse and mesopore shrinkage [40-42].

CLASSIFICATION OF AEROGEL-BASED BIOMATERIALS

They are classified based on two distinct properties which include: constituent materials and chemical properties [9]. Nanomaterials is one of the materials used in biomedical application [50-54].

ORGANIC AEROGELS-BASED BIOMATERIALS

Unique characteristics associated with organic aerogels include: light weight, flexibility and biocompatibility [55-58]. Carbon based aerogels are constructed with the help of carbon-based nanomaterials. The materials exist in form of nano diamonds (NDs) [59-62]. Another component of the aerogel production are the organic polymer materials [63-65]. Cellulose has a well-known cellulose-based hydrogel derived from it [66].

INORGANIC AEROGEL-BASED BIOMATERIALS

The foundation of these biomaterials consists of inorganic materials like metal oxides [63-65]. The first synthesis of silicon aerogels was in the 19th century [58]. Inorganic aerogels have wide applications such as a thermal insulator in aerospace and construction. They are also used in industrial setting and in water purification [65].

HYBRIDIZED AEROGEL-BASED BIOMATERIALS

Distinct properties of aerogels are influenced by the selection between organic and inorganic types. They possess notable characteristics such as biodegradability, biocompatibility and light weight [69,70]. A significant milestone was achieved by Novak [71], when he prepared the first silica (SiO2) hybridized aerogel for specific applications [71]. There are various techniques deployed in the characterization of organic-inorganic hybrid aerogels [71,72]. There are two main classes of organic-inorganic hybridized aerogels [73,74]. The choice of type I or type II hybridized aerogels depends on its application [75].

AEROGEL-BASED STRATEGIES FOR TISSUE REGENERATION

Properties such as biocompatibility, hydrophilicity and non-cytotoxicity are exhibited by aerogels.

CONCLUSION AND FURTHER PERSPECTIVE

The new characteristics of aerogels make them stand out as a unique material. There is need to pay critical attention on the synthesis protocols and porosity regulation of aerogels. Inherent properties of aerogels can be further explored by researchers in areas of aerogel-based biomaterials.

AUTHORSHIP CONTRIBUTION

Ezegbe Chekwube Andrew: Writing, review, supervision, Ezegbe Amarachi Grace: Writing, review, Odo Kenechi Benjamin: Writing, review, Onyia Oluebube Chisom: Review, writing, Agu-Kalu Amarachi: Writing, review.

ACKNOWLEDGEMENTS

Authors wish to acknowledge the librarian and other technical staffs at Federal University of ABC (UFABC) for providing us with the necessary materials and tools.

CONFLICT OF INTEREST

Authors declare no conflict of interest

No Files Found

Share Your Publication :