-

Publish Your Research/Review Articles in our High Quality Journal for just USD $99*+Taxes( *T&C Apply)

Offer Ends On

Chana ZM*, Yakubu AK, Girgiri AY, Kolo UM, Saidu AM and Yerima J

Corresponding Author: Zuwaria Mohammed Chana, Department of Animal Science, Faculty of Agriculture, University of Maiduguri, P.M.B. 1069, Maiduguri, Borno State, Nigeria.

Received: January 05, 2023 ; Revised: March 10, 2023 ; Accepted: April 10, 2023 ; Available Online: May 31, 2023

Citation: Chana ZM, Yakubu AK, Girgiri AY, Kolo UM, Saidu AM, et al. (2023) Chemical Composition and Rate of Ruminal Degradation of Four Different Varieties of Hydroponic Sorghum Fodder Harvested at 8th Day. J Vet Marine Res, 3(1): 1-7.

Copyrights: ©2023 Chana ZM, Yakubu AK, Girgiri AY, Kolo UM, Saidu AM, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Views & Citations

Likes & Shares

An experiment was conducted to evaluate the chemical composition and rumen degradability of four different varieties [Red chakalari (V1), White chakalari (V2), Kaura (V3) and Jigari (V4)] of hydroponic sorghum fodder (HSF). Three (3) fistulated rams were used, each serving as a replicate at 0, 3, 6, 12, 24, 48, 72 and 96 h incubation period using the equation Y = a + b (1 - e-ct). The experiment was designed on a randomized complete block design (RCBD) 2-way classification. Factor A was the different incubation periods while factor B was the different varieties of HSF. The results for chemical composition of the different HSF were inconsistent among the varieties but, V4 had the highest crude protein (14.05%) value and lower fibre contents. Significant (P<0.05) differences were shown in degradation rates at 0 and 3 h incubation periods among the varieties. However, no significant (P>0.05) variation was observed in the remaining incubation periods between the HSF varieties, but degradability rate increases with increase in incubation time. This study revealed that the four HSF varieties had better chemical composition and were well degraded in the rumen of ram with more than 60% degradability at 48 h. However, Jigari variety (V4) was superior in effective degradability.

Keywords: Hydroponic fodder, Sorghum varieties, Rumen degradation

INTRODUCTION

Existing feedstuff in most tropical areas often provide inadequate energy, protein, mineral and vitamins to support animal production [1]. Animals are fed predominantly with high fibre feed that are deficient in nutrients especially for microbial fermentation [2]. The situation is worse during the long dry season which lasts for about 7-8 months in Sahel Savanna region of Nigeria. During such period, fibre-rich low-protein forages and crop residues are the most abundant feed for ruminants. Methods and technologies were therefore required to improve production of forage like hydroponic system.

Hydroponics is a technique whereby green fodder of many plants are produced without soil in a hygienic environment free of chemicals [3-5]. It is a continuous fodder production throughout the year without requiring extensive land and less water consumption [6]. The special features of hydroponic system make it one of the most important agricultural techniques currently in use for green fodder production in many countries especially in arid and semi-arid regions of the world in view of its utilization [7].

Utilization of different feedstuffs by ruminant animals is largely dependent upon microbial degradation within the rumen. Therefore, the description of different feedstuffs in terms of their different degradation characteristics would provide a useful guide for ranking on the basis of nutritive value. The use of nylon bag technique in estimating both the rate and extent of disappearance of feedstuff from the rumen has been described [8]. The simplicity and cost effective of the technique necessitate its wide usage for feed evaluation especially in developing countries. The current study was designed to determine the chemical composition and the nutrient degradation characteristics of four varieties of hydroponic sorghum fodder.

METHODOLOGY

Study Area

The experiment was carried out at the Livestock Teaching and Research Farm University of Maiduguri. Maiduguri is situated at latitude 11° 51lN and longitude 13° 09lE at an altitude of 354 m above sea level [9], which falls within the

semi-arid zone of West Africa. The area is characterized by short period of rainy season (June to September) with annual rainfall ranging from 500 to 600 mm followed by long dry season [10]. Ambient temperatures are high (38-44°C) in the months of March to May whereas low temperatures were recorded in December and January ranging from 15-19°C. Low relative humidity is prevalent in the month of March and high in the month of August [10].

Hydroponic Fodder Production

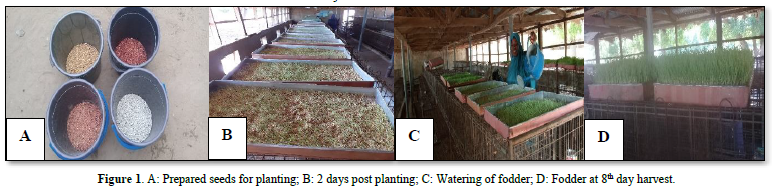

A hydroponic unit was constructed at the Livestock Teaching and Research Farm University of Maiduguri and installed into growth room (an improvised greenhouse). The growth room was constructed with cemented floor, walls of nets and roofed with aluminum sheets surrounded by trees which provide additional cooling and ventilation to the room. The unit was made up of metal frame containing shelves. Aluminum planting trays were made with holes at the bottom to allow drainage of excess water in order to prevent logging of water. Knapsack sprayer, watering can, buckets and four varieties of sorghum seeds were used during the fodder production. The varieties of the seeds used were Red chakalari (V1), White chakalari (V2), Kaura (V3) and Jigari (V4) which were commonly grown in the research area owing to their adaptability and affordability. The seeds were cleaned, weighed, washed thoroughly and soaked in water for 24 h then rinsed with clean water before planting. The planted seeds were watered twice daily and fodder were harvested at 8th day post planting (Figure 1).

Experimental Animals

Three (3) Balami rams weighing 38kg ± 2kg were used for the rumen degradation studies. They were cannulated and admitted at the University of Maiduguri Veterinary Teaching Hospital. The rams were fully recovered 4 weeks after the operation. They were moved to the research farm and allowed 14 days adjustment period prior to the commencement of the research. The cannulated area was disinfected daily to prevent infection and each ram served as a replicate. They were all fed with similar concentrate diet to have same rumen condition so as to avoid bias (Figure 2).

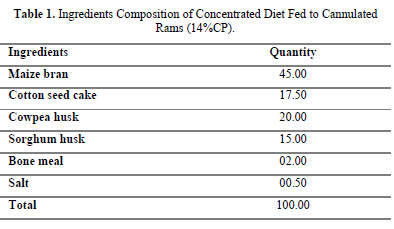

Diet for Cannulated Rams

A concentrate diet was formulated to contain 14% crude protein (CP) using the following ingredients: maize bran, cotton seed cake, sorghum husk, cowpea husk, bone meal and mineral salt. The animals were fed ad libitum and ingredients composition of the concentrate diet was presented in Table 1.

Samples Preparation for Incubation

Samples of the four varieties of HSF at 8th day harvesting time were obtained and dried at 105°C for 24 h. One hundred grams (100g) of oven dried samples were ground for determination of chemical analysis. Another 100g of the oven dried samples were ground roughly for degradation analysis. The chemical composition of each sample was analyzed on dry matter basis before incubation [11].

Incubation Procedures

Degradation study was conducted on dry matter basis of the four varieties of fodder harvest using the following incubation procedures:

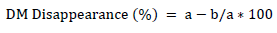

The DM of the sample residues were determined and the DM disappearance was calculated using the following formula proposed by Orskov and McDonald [12].

Where:

a: weight of sample before incubation; b: weight of sample after incubation

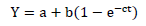

The rate of DM degradation was calculated by fitting values to the exponential equation of Orskov and McDonald [12].

Where:

Y: degradability at time t; a: intercept (washing losses at zero-time intercept); b: potentially degradable fraction with time t; c: rate constant for degradation of b; t: time

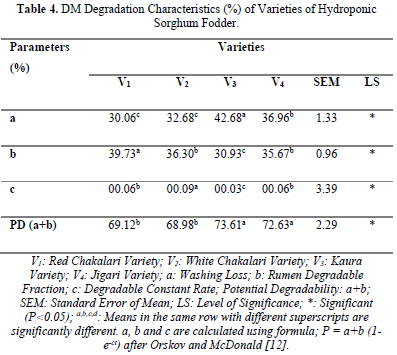

The effective DM degradability of the feedstuff based on the different ruminal outflow rates was calculated [8] using the equation:

Where:

ED: Effective degradability; a, b and c being constants from the equation above; k: fractional outflow rate

Experimental Design

The experimental design for the degradability studies was based on randomized complete block design (RCBD) in a 2-way classification. Factor A was the different incubation periods (0, 3, 6, 12, 24, 48, 72 and 96) while factor be B was the different varieties of HSF.

Chemical Analysis

Samples collected were analyzed on Dry Matter (DM) basis for Crude Protein (CP), Ether Extract (EE), Crude Fibre (CF) and Ash according to AOAC [11]. Acid Detergent Fibre (ADF) and Neutral Detergent Fibre (NDF) were determined using the method of Van Soest [13]. Organic Matter (OM) and Nitrogen Free Extract (NFE) were calculated.

Statistical Analysis

Data collected were subjected to analysis of variance (Statistixs 10) in a Randomized Complete Block Design, potential and effective degradation were computed using Non-Linear Regression analysis of SPSS (version 23) package. The rate of DM disappearance was analyzed using Newayprogramme [12]. Correlation coefficients and regression equations were used to show any relationship between parameters measured.

RESULTS

Chemical composition of four varieties of HSF harvested at 8th day

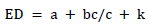

The result of the chemical composition of the fodder was presented in Table 2. Mean dry matter percentage was high in V3 with 16.35% and lowest in V2 (12.10%). The crude protein contents were 11.7, 10.6, 09.31 and 14.50% for V1, V2, V3 and V4 respectively. The mean organic matter ranged from 10.60% in V1 to 14.95% in V2. Values of neutral detergent fibre and acid detergent fibre ranged from 37.14 to 44.69% and 20.83 to 31.32% respectively. Hemicellulose was low in V4 with 13.37% while V2 had the highest value of 16.31%.

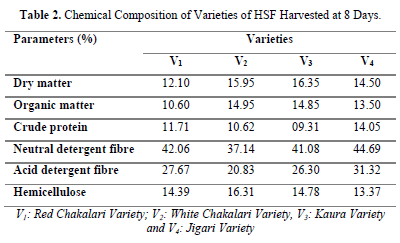

Dry matter disappearance (%) of HSF varieties

The actual dry matter disappearances of the four varieties of HSF were shown in Table 3. There were significant (P<0.05) differences in degradation rates at 0 and 3 h among the varieties. The highest rates of 34.33 and 44.33% in V3 and lowest (20.44 and 32.27%) in V1 were recorded in respect of 0 and 3 h incubation periods. No significant (P>0.05) difference was observed in the remaining incubation periods among the varieties but degradability rates were more than 40% for all the varieties at 6 h. DM disappearance rate surpasses in V4 with 57.33% at 12 h. Inconsistency exist between the HSF varieties but the degradability rate increases with increase in incubation time. Highest degradation percentage of 75.56% was recorded in V4 at 96 h incubation period, while least value was recorded in V1 with 72% at same hours.

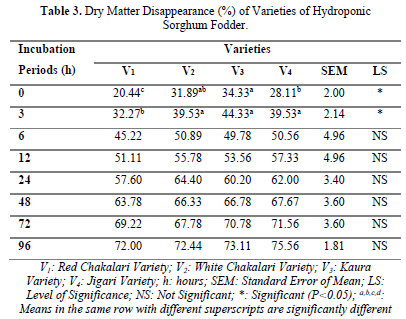

Dry matter degradation characteristics of four varieties HSF

The degradability characteristics of HSF varieties were presented in Table 4. There were significant (P<0.05) differences in the degradability characteristics. Mean potential degradability (PD) values of 69.12, 68.98, 73.61 and 72.63% were recorded for V1, V2, V3 and V4 respectively, with the highest value of 73.61% in V3 and the lowest in V1 (69.12%). The washing loss (a) for the four varieties of HSF were 30.06, 32.68, 42.68 and 36.96% for V1, V2, V3 and V4 respectively which were ranked as V3>V4>V2>V1. The degradable fraction (b) were 39.73, 38.30, 30.93 and 35.67% for V1, V2, V3 and V4 respectively. The potential degradability of any feed materials is its washing loss (a) plus the rumen degradable fraction (b).

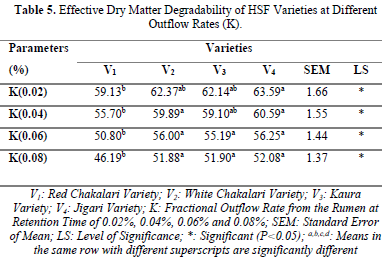

Effective dry matter degradability of HSF varieties at different outflow rates (K)

Outflow rates of four varieties of HSF were presented in Table 5. Significant (P<0.05) differences were observed in effective degradation percentages between the HSF varieties and at each of the retention time. Higher values of fractional outflow rates were recorded in all the varieties at rumen retention time of 0.02. It was indicated that V4 values were higher than the other varieties at each of the different retention time.

DISCUSSION

Chemical composition of HSF varieties

There were changes in chemical composition among the different varieties of HSF at 8th day harvest. The values of dry matter (12.10 to 16.35%) recorded in the current study was in conformity with the report of Sneath and McIntosh [14] who reported that the various commercial hydroponics fodder producers claimed yields of 6 to 10 times with dry matter percentages of 6.4 to 20%. Furthermore, Naik and Singh [15] postulated that maize hydroponic fodder produces 5 to 6 kg from 1kg seed with dry matter content of 11 to 14%. Similarly, Naik [16] also reported that dry matter and organic matter contents of hydroponics fodder decrease may be due to decrease in starch content. During sprouting, starch is catabolized to soluble sugars for supporting the metabolism and energy requirement of the growing plants for respiration and cell wall synthesis, so any decrease in the amount of starch causes a corresponding decrease in dry matter and organic matter [17].

The crude protein content (09.31 to 14.05%) in present study were similar to the range of 8.88 to 13.5% obtained in hydroponic maize at 1 to 7 days harvest [16]. Conversely, Christidiana [6] reported higher CP values of 13.94 and 17.27% in respect of KD4 HSF and Super -1 HSF at 8 days harvesting time. Consequently, hydroponic barley was reported to have 25.2% CP at 10 days period [5]. Hydroponic maize was also harvested at 7 days with 13.3% CP [18]. Higher CP contents in hydroponic fodder is attributed to the loss in DM particularly carbohydrates through respiration during germination. This indicates that the CP content obtained for all the four varieties of HSF was sufficient for ruminants. Lesser values (27.14 to 44.69%) of NDF recorded in the current study was in conformity with values (24.98 to 49.52%) reported by Zelalem and Gurmesa [19] who studied different varieties of HSF, however, the ADF (20.83 to 31.32%) values were higher than those reported (7.04 to 19.43%) by Zelalem and Gurmesa [19]. Also, Al-Karaki and Al-Momani [5] recorded lower values of ADF (14.3%) and NDF (29.6%) for hydroponic barley fodder, while Owens [20] reported ADF values of <30-35% and NDF (<40-45%) in his findings, which agreed with the values obtained in the current study. Lower values of NDF and ADF in fodder are considered as good nutritional values because Sneath and McIntosh [14] concluded that digestibility of forages decrease with increasing fibre content. However, increase in NDF and ADF values occur as a result of synthesis and accumulation of lignin which usually occurs during the formation and thickening of secondary cell walls.

Dry matter disappearance (%) of four varieties of HSF

More than 50% DM disappearances was recorded at 12 h incubation period in this study with the highest percentage in V4 (57.33%). This was higher than 30% disappearance at 12 h in barley sprout reported in the study of Dung et al. (2010). Abubakar [21] reported a range value of 24.30 to 37.37% at 12 h for Panicum maximum mixed with forage legumes. Similar value (53.40%) was obtained in lablab forage incubated 12 h [22]. It was observed that DM disappearance increases with increase in the incubation time and this shows that HSF is highly degradable in the rumen. The extent of degradation after 48 h of incubation was good for all the HSF varieties as it was above 60%. This implies good digestibility potential for these fodders when grown as feed resources for ruminant livestock as 48 h degradability is often considered to be equivalent to digestibility [23].

DM degradation characteristics of HSF varieties

The solubility (a) of dry matter obtained in the current study ranged from 30.06% for V2 to 42. 68% for V4. The amount of dry matter degraded in the rumen with time (b) is in the following order: V3>V2>V4>V1. The degradation rate (c) of the dry matter of the various HSF ranged from 0.03 for V3 to 0.09 for V2 and the values were significantly (P<0.05) different from each other. The “c” values recorded in this work were higher than the 0.03 reported for lablab [24] and 0.04 for groundnut haulms [25]. The potential degradability (a+b) differed significantly (P<0.05) with the following ranking: V3>V4>V1>V2. The in situ “c” fraction has been suggested to be a good predictor of intake [26].

Effective DM degradability (%) of HSF varieties at different outflow rates (K)

The effective degradation depends on how long the feed remains in the rumen and is a function of quality and quantity of feed fed to an animal [27-29]. The effective degradability (ED) for different HSF in the current study were higher in all the varieties at retention time of 50 h (K =0.02) in the following order: V > V2 > V3 > V1. The values obtained in this work were higher than the range of 51 to 69% reported by Abubakar [1] for tropical forage legumes and 35.98 to 50.89% for Panicum maximum mixed with tropical forage legume by Abubakar [21].

CONCLUSION

It is concluded from the results of this study that hydroponic sorghum fodder made from four varieties of V1, V2, V3 and V4 harvested at 8th day had good fodder nutrient contents and were well degraded in the rumen of rams with more than 60% at 48 h. However, V4 was superior in the degradation studies.

No Files Found

Share Your Publication :