-

Publish Your Research/Review Articles in our High Quality Journal for just USD $99*+Taxes( *T&C Apply)

Offer Ends On

Baya F* and Mubvekeri W

Corresponding Author: Baya F, Cotton Research Institute, P. Bag 765, Kadoma, Zimbabwe.

Received: June 13, 2023 ; Revised: June 16, 2023 ; Accepted: June 19, 2023 ; Available Online: June 28, 2023

Citation: Baya F & Mubvekeri W. (2023) Effect of Ratoon Cotton Production on Seed Cotton Yield. J Agric For Meterol Stud, 2(1): 1-6.

Copyrights: ©2023 Baya F & Mubvekeri W. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Views & Citations

Likes & Shares

Production of cotton from ratoon has been a major challenge affecting productivity in some cotton growing countries. Ratoon is cotton regrowth arising from root stock of a previous season. Zimbabwe put in place a legislative tool known as the Plant Pests and Diseases Act, Chapter 19:08 which stipulates the earliest cotton planting, slashing and destruction dates are to ensure that the cotton closed season, also known as the dead period of 66 days be achieved. This agronomic practice of ratoon carryover had to be evaluated hence the study was conducted at Cotton Research Institute from 2019 to 2022 season so as to determine the effect of ratoon cotton on seed cotton yield. Six treatments were generated which included. 1- Previous crop not slashed: 2- Stalks cut at ground level at slashing deadline: 3- Stalks cut on seed planting date with effective rain: 4- Stalks cut at the bottom-most monopodial branch at slashing deadline: 5- Cut at the bottom-most sympodial branch at slashing deadline and 6- Established crop from seed. The six treatments were laid in a Randomized Complete Block Design with four replications. The gross plots were 264m2 and net plots 180m2. Measurements were on average boll number, average boll mass, and seed cotton yield and plant height. Data analysis was done using GenStat 18th edition. Data analysis was done using GenStat 18th edition. According to the results from an across season analysis, highly significant differences were recorded (P<0.01) on yield where treatment 6 had highest yield of 914 kg ha-1 whereas for the ratoon crop on Treatment 1 the yield was 555 kg ha-1. It took two seasons to cause decline in yield on the ratoon crop in Treatment 1 where in 2020 the yield was 407 kg ha-1 and in 2022 the yield declined to 272 kg ha-1. Tallest plants were recorded on Treatment 1 with 192cm. High number of bolls were recorded on treatment 6 with an average of 13 bolls, however bolls were ranging between 14 to 22 bolls per plant on the same treatment. There were no significant differences in the boll mass. The practice of producing cotton from ratoon resulted in declining in yield.

Keywords: Ratoon, Sympodial branch, Apical meristem

INTRODUCTION

Production of cotton from ratoon has been a major challenge affecting productivity in some cotton growing countries. Ratoon cotton is a crop in which the stalks are cut down after harvest, but the rootstock is left in the ground to re-grow the following season. These plants are more prostrate and bushier than the original crop, as all branches from the main stem are vegetative [1]. Zimbabwe has put in place a legislative tool known as the Plant Pests and Diseases Act, Chapter 19:08 which stipulates the earliest cotton planting and cotton slashing and destruction dates to ensure that the cotton closed season, also known as the dead period of 66 days from the latest stalk destruction date to earliest planting date is achieved. It is recorded elsewhere that ratoon is a favorable host for the mealybug, the earliest and latest Helicoverpa generations. Pink bollworm is controlled by use of a closed season between cotton crops, sanitation on and off the field and finally use of pesticides. Sanitation on and off the field is effective in destroying resting larvae [1,2].

Early termination of the cotton crop and prompt plough down after harvest suppresses pink bollworm by reducing the number of pink bollworms entering diapauses [3]. Inoculum for soil borne diseases (Fusarium, Verticillium) build up in ratoons. Since ratooning of cotton is highly complex and leads to problems, such as the accumulation of pests and diseases, decreased boll size, stand loss during severe winters, and harmful regrowth during mild winter. According to Glen [4], branching of the main stem of cotton occurs initially from auxiliary buds of the main stem leaves generally referred to as main stem nodes giving rise to vegetative or monopodial and fruiting or sympodial branches. Below a certain point on the main stem the branches are monopodial, and above that point they are sympodial [1]. This point is referred to as the node of the first fruiting branch.

Vegetative branches just like the main stems have got one meristem. They therefore grow straight and erect and do not bear flowers directly, but produce fruiting branches which do. Fruiting branches on the other hand have multiple meristems and have a zigzag growth habit. They terminate at each node with a flower bud, and a lateral branch, which repeats the process. The extended vegetative growth period tends to enhance fiber immaturity, reduce lint development and also increases costs of production by increasing the number of weeding and sprays and the length of time crop is on the farm [5]. Therefore, due to all these assumptions on ratoon crop, this led to a study in order substantiate the real effects of this agronomic practice.

OBJECTIVE

To determine the effect of ratoon cotton on seed cotton yield.

MATERIAL AND METHODS

Experimental location

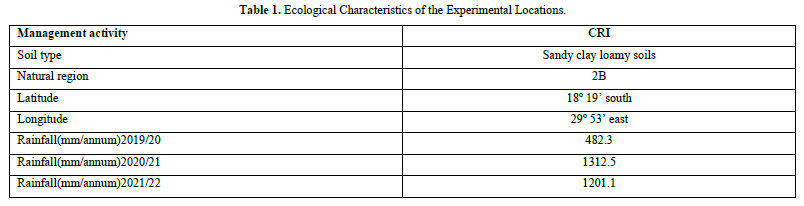

The study was conducted at Cotton Research Institute (CRI) from 2019 to 2022 season. CRI is situated near Kadoma in Natural Agro-ecological Region 2B on latitude 18o 19’ South and longitude 29o 53’ East. The altitude of the trial area was 1152m. The soil was sandy clay loamy. The selection of the location was influenced by the need to isolate the ratoon in order to minimize spread of pests and diseases to other cotton crops. Therefore, the trial area was separated from other potential cotton fields by a 200m gum plantation.

Treatments

The experiment had 7 treatments as follows:

Experimental Design and Plot Sizes

The six treatments were laid in a Randomized Complete Block Design (RCBD) with four replications. The gross plot was 22 meters (23 rows) x 1metre x 12 meters = 264m2. The net plot was 18 meters (19 rows) x 1-meter x 10 meters = 180m2. On the first season, the treatments had same management practices, treatment application were done in the following season in year 2021 which included cutting cotton stalks at different positions using secateurs.

Trial management operations

During the first season, all treatments were put in four replications and were provided with uniform management. Season 2, application of treatments was done. Uniform land preparation was only done for Treatment 6 in the second and third season. Application of Compound L at a rate of 250 kg/ha before planting was also done and top dressing was applied at a rate of 150kg/ha, 8 weeks after crop emergence in all treatments. Planting was done same day with first effective rains at a spacing of 1.0 m x 0.3 m and depth of 20 mm and gap-filling was done within 5 days after emergence. Thinning to leave one healthy seedling at 30 cm apart was done within two weeks after crop emergence. Pre and post emergence herbicides were applied accordingly and hand hoeing was done whenever necessary in order to keep the crop weed free. Scouting for pests on weekly basis was done starting at 2 weeks after emergence on Treatment 6 and on all other treatments it commenced on the day of planting Treatment 6. Spraying pesticides were done when necessary depending on scouting results. Harvesting commenced when 3-4 bolls per plant had split and every 14 days thereafter.

Measurements and Statistical Analysis

Seed cotton yield was measured. Data for average boll mass, boll number per plant and plant height were collected for the purpose of explaining the performance of treatments in respect of seed cotton output. Analysis of data for the dependent variable was done using GenStat software 18th edition. In the final season an across three seasons analysis of data was performed. Means for seed cotton yield were separated using Fisher’s Protected LSD at 5%.

RESULTS AND DISCUSSION

Effect of Treatments on Seed Cotton Yield (kg/ha)

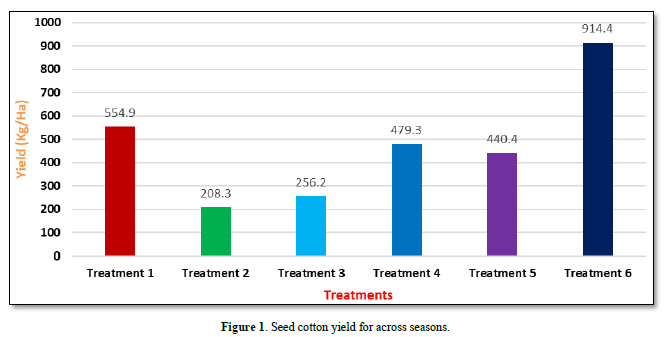

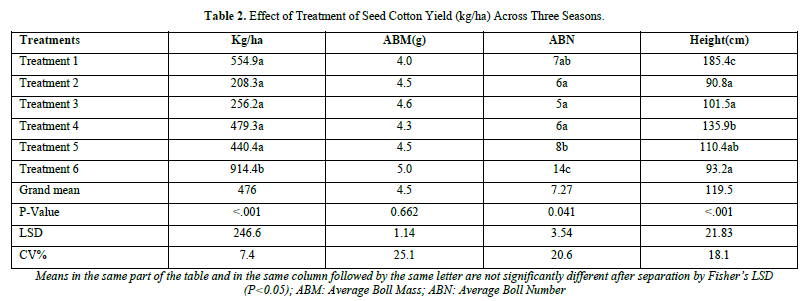

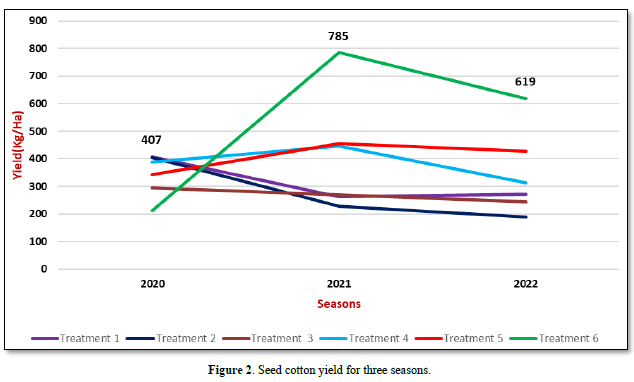

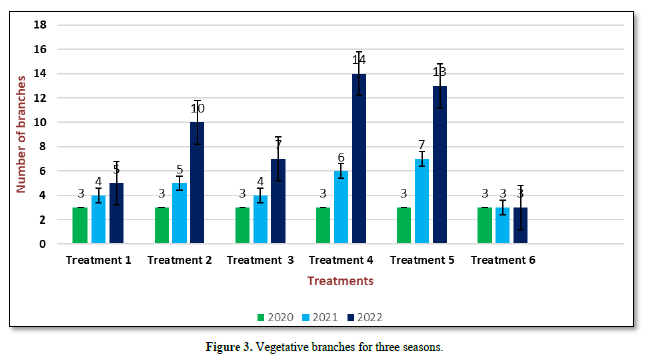

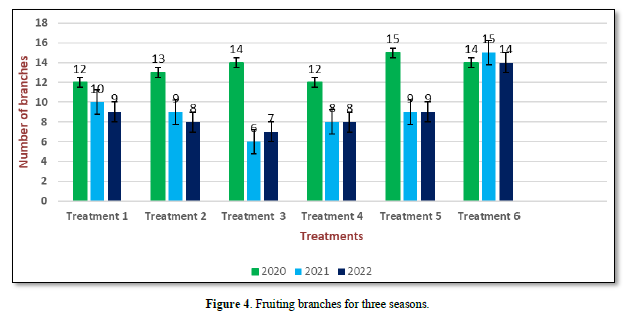

The results obtained on the across season analysis showed that that seed cotton yield obtained from Treatment 6 (Crop established from the seed) had significantly highest (P<.001) at 914 kg, (Table 1 & Figure 1). The highest yield recoded on across season was being attributed to less pest damage since the crop was established from the seed. According to the results a farmer harvest more from crop established from seed unlike from a ratoon crop, the reason being that a ratoon crop will require more chemicals to control the pests of which one cannot fully succeed on controlling them especially pests like bollworms and jassids. Treatment 6 produced higher average number of bolls per plant with 14 and yet the shortest plants, Treatment 5 had an average number of bolls of 8 then followed by Treatment 1 with 7 bolls and the remaining three treatments had comparable results, however number of bolls were ranging between 5 to 30 bolls per plant. The higher number of bolls in Treatment 6 contributed to the highest seed cotton yield in the same treatment. Looking on the number of bolls in all treatments, it clearly shows that plants carry-over does not necessarily mean that the farmer will be having an advantage on yield actually its detrimental as you will lose 100% bolls (Table 2) as compared to crop established from seed. Seed cotton yields for the rest of treatments were statistically comparable. Treatment 6 had the lowest and constant number of vegetative branches and the highest number of fruiting branches in the second and third season, that was due to the behavior of plants when the apical meristem was terminated where the plant tend to compensate by developing more coppices, and those coppices were vegetative branches which do no bear fruits that is why there were more of increase in vegetative branches at the expense of fruiting branches on Treatment 1 to 5 as we move from the first season to the third season (Figures 2 & 3). From the analysis on (Figures 2 & 3), the low performance of Treatments 1 to 5 in terms of seed cotton yield could be attributed to poor insecticide spray penetration due to the denseness of the foliage due to the high number of vegetative branches, (Figure 2) and due to few fruiting branches, (Figure 3). The seasonal seed cotton yields for Treatments 1 to 5 were subdued over the lifespan of the experiment. Seasonal yield declined continuously for 3 years for Treatments 1, 2 and 3 (Figure 1).

The relationship between treatments on across season analysis

According to the line graph above (Figure 1), Treatment 6 had lowest seed cotton yield in the first year 2020 with 212 kg ha-1 and the yield rose up by close to 100% to 785 kg ha-1 in the second year as this was due to different amount of rainfall recorded in the two seasons. However, in the third year the yield slightly dropped to 619 kg ha-1 though it still remained as the highest yield when compared to the other treatments. In year 2020, Treatment 1 had highest yield with 407 kg ha-1 and in the next season it drastically dropped to 262 kg ha-1 and finally in 2022 it was at very low at 272 kg ha-1, this means that the yield on Treatment 1 started to drop in the following year (2021) after the ratoon practice had started to be initiated. Other ratoon practices from different treatments also produced comparable seed cotton yield results as they never exceeded 500 kg ha-1 mark. This simply implies that despite practicing different types of ratooning, they remain performing below the traditional practice of establishing a crop from seed.

Effect of Ratoon on vegetative branches

According to the graph above, Treatment 6 maintained same number of vegetative branches across all the three seasons with an average of 3, this implies that the plants were not densely populated hence pest management was not so difficult. Treatment 6 where stalks were not slushed, the vegetative branches increased each year but not exceeding 6. Highest number of vegetative branches were recorded in the third year on Treatment 2, 4 and 5 where there were exceeding 10. These highest number of vegetative branches influenced the declined on the fruiting branches within the same treatments. The number of regenerated ratoon cotton plants and sprouted stems increased with increases in cut height.

Effect of Ratoon on fruiting branches

According to Figure 3 above, Treatments 1 to 5 had higher number of fruiting branches in the first year but later dropped drastically the following year (2021). As for Treatment 6, it maintained higher number of vegetative branches for all the three seasons and it contributed to higher seed cotton yield when being compared with the other treatments.

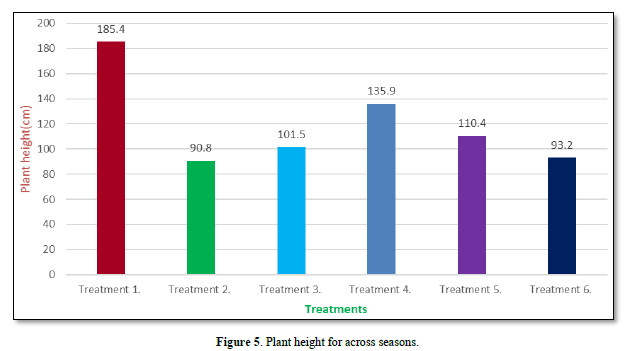

Effect of Ratoon on plant height

According to Figure 4 below, Treatment 2 and 6 has almost similar plant heights of 90.8cm and 93.2cm respectively as these were shorter plants. Treatment 6 was established from planting seed cotton and Treatment 2; the plants were cut from the ground level on the same day when Treatment 6 was planted. Treatment 3 to 5 had almost similar plants in height though they were much taller than Treatment 2 and 6 and the reason being that these Treatment 3, 4 and 5 had plants cut at different levels from the ground, so these were already established stalks which just regenerated as they developed new shoots. Treatment 1 had tallest plants with an average height of 185.4cm because these were unlashed stalks throughout the trial duration for three years so they kept growing taller (Figure 5).

CONCLUSIONS

The practice of producing cotton from ratoon resulted in subdued seed cotton yield as this was evident from the results obtained. Ratooned plants on treatment one, two, three, four and five resembled better yield in the first year but the yield declined drastically in the second and third season. This was influenced by the build-up of pests especially bollworms leading to severe boll damage. Spraying and weeding became a challenge as the plants were now densely populated in the third season. A significant decline in the yields can be observed in such plants because ratooning causes crowding and the soil does not have time to get replenished. In general, the ratoon yields are lower as compared to the crop yields.

RECOMMENDATIONS

The regulatory and legislative tools that have been put in place to discourage the production of cotton from ratoon in Zimbabwe need to be complied with and strongly enforced in order to enhance cotton productivity.

No Files Found

Share Your Publication :